RongXing Carbon Introduction

RongXing group was founded in 1992, which is a group company combining Calcined Petroleum Coke, Electrode Paste, Graphite Electrode and Refractory production. Our company produces 250000 tons of Calcined Coke, 200000 tons of Electrode Paste, 30000 tons of Graphite Electrodes and 20000 tons of Refractories annually.

RongXing group focuses on product quality and reputation, creating value for employees.

In the planning of the company, we will develop agents in more countries and regions, vigorously support agents to create warehouse, display and store our products, and create an online trading platform around the world to help customers expand the market.

As a ISO9001:2016 certified supplier, possessing sophisticated production lines and inspection equipments, providing diverse lines of carbon metallurgical products backed by expert R&D technical support, we develop closer customer relationships and taking on a larger role in the total supply and manufacturing chain. The diverse products include carbon materials and graphite materials.

Exporting first-class carbon metallurgical products to the world as a mission, as a pilot enterprise of One Belt and One Road initiative pilot enterprise, Rongxing Group grasps the opportunity to vigorously develop overseas markets. Our graphite electrode and electrode paste products have been exported to Europe, Asia, Africa, South America and Middle Eastern countries, which enjoys good reputation.

Rongxing group will become a direct platform for industrial products factory, which is based on metallurgical casting materials.

Electrode Paste Profile

The electrode paste is dehydrated and melted by petroleum coke and pitch coke in a melting tank, and proportionally added to the kneading pot and kneaded, then molded and calcined.

It has the characteristics of low resistivity and is used as a conductive material in electric furnace equipment such as ferroalloy furnace and calcium carbide furnace. Electrode paste can be said to be a simple and technically complicated product in carbon production. After being kneaded and molded, the electrode paste became a finished product. Unlike other carbon and graphite products, when defects occur in the previous process, it can be compensated by baking, graphitization or even an impregnation process.

The electrode paste is calcined by the heat in the submerged arc furnace. There- fore, the consumption speed of the electrode and the calcination speed are the key to the use of the electrode paste. As the submerged arc furnace technology gradually develops toward

large-scaled and air-tightness, during the calcining process, the electrode develops from the old type opened furnace type to the closed furnace type, and the heat obtained by the electrode from the furnace is greatly reduced, which requires an increase in the sintering perfromance of the electrode paste to compensate for this deficiency.

Rongxing-made electrode paste products are being used in the electric equipment such as ferroalloys furnace, carbide furnace as a conductive material.

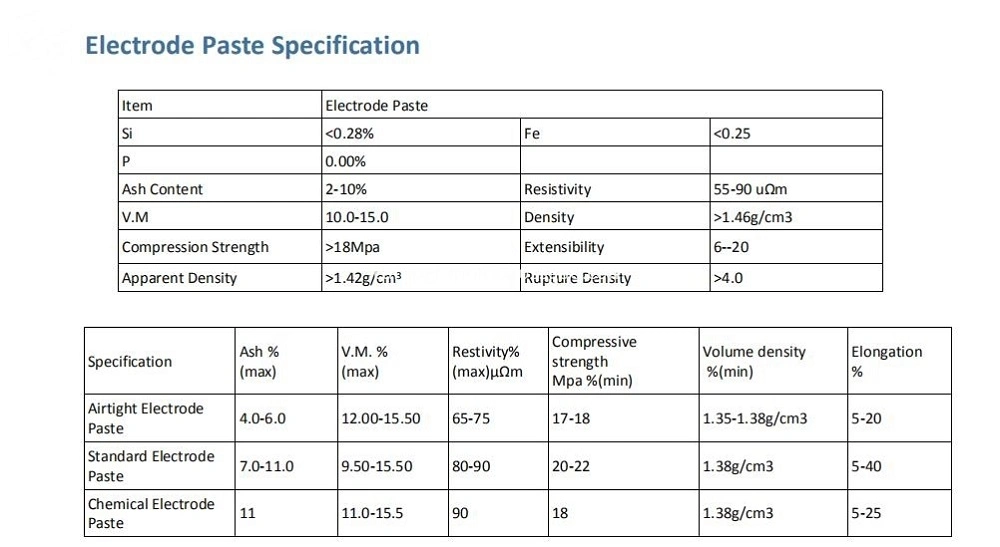

Specifications for Electrode Paste

Package of Electrode Paste

The main raw material of our electrode paste is the authentic Ningxia Taixi anthracite, and the raw materials also include graphite scrap with a carbon content of 99.9%. The product has the characteristics of low ash content, low V.M, high carbon content, low electrical resistance and high strength, and the consumption is 20% lower than that of the rivals. In order to further improve the output and quality of electrode paste, the world's advanced manufacturing technology and production process have been introduced. Using a fully automatic production line, most of the procedures of ingredient, crushing, kneading and forming are competed by computer control. The electrode paste finished product is more suitable for the needs of submerged arc furnace with more accurate recipe, which meet customer's requirement.

Notes for Rongxing Electrode Paste

For Rongxing-made electrode paste manufacturers, the two most taboo problems are soft and hard electrode breakage, of which soft breakage is even more terrible and can easily cause accidents. Hard breaking is caused by insufficient strength of the electrode paste after sintering; soft breaking is because the electrode sintering speed is not as fast as the consumption speed, and the lowering is too fast. The electrode cannot be fully sintered and cannot withstand the tensile and lateral impact of the lower part of the electrode, causing fracture. These two problems are directly related to the performance of the carbon manufacturer's electrode paste, and also related to the operation during use.

Notes for Rongxing Electrode Paste

For Rongxing-made electrode paste manufacturers, the two most taboo problems are soft and hard electrode breakage, of which soft breakage is even more terrible and can easily cause accidents. Hard breaking is caused by insufficient strength of the electrode paste after sintering; soft breaking is because the electrode sintering speed is not as fast as the consumption speed, and the lowering is too fast. The electrode cannot be fully sintered and cannot withstand the tensile and lateral impact of the lower part of the electrode, causing fracture. These two problems are directly related to the performance of the carbon manufacturer's electrode paste, and also related to the operation during use.